The animal feed mill equipment for sale is used to make 2-12mm feed pellets suitable for the growth of animals. RICHI animal feed equipment is mainly suitable for the pellet production of poultry, livestock, rumination, aquatic animals, and so on. The 1-2t/h animal feed mill equipment for sale is mainly designed for small farm owners.

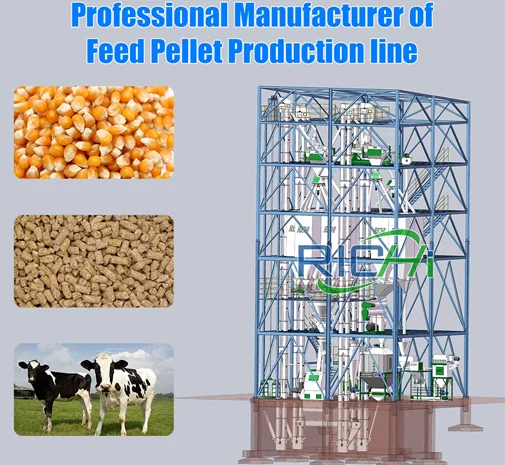

As the above picture shows, the main sections of the animal feed pellet mill equipment for sale are the crushing and mixing section, pelletizing section, and the cooling and packing section. The main equipment of a complete animal feed mill equipment for sale includes feed grinder machine, feed mixer machine, animal feed pellet machine, pellet crumbler, counterflow pellet cooler, screening system, automatic packing machine, conveying equipment, etc.

Firstly put the raw materials of a specific proportion into the screw conveyor. Then the raw materials would be crushed into powder by the feed grinder machine. After that, the powder would be completely mixed in the feed mixer machine.

After mixing, the powder is conveyed into the conditioner by the variable frequency feeder. And in the conditioner, the powder is fused with steam. After reaching a certain temperature and moisture, the powder enters the pelletizing chamber. Then the powder is strongly squeezed by the ring die and the pressure roller to form pellets. Under the strong compression of the ring die and the pressure roller, the granules are formed and then cut into the desired length by the cutter.

Then, the conveyor puts the pellets into the cone bucket. The pellets pass through the cone bucket and are discharged into the counterflow pellet cooler. Then the pellets get through the screening system. After sieving, the pellet can be packed.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

A complete animal feed manufacturing plant includes pre-cleaning system, crushing system, mixing system, pelletizing system, cooling system, screening system, and packing system.

The raw materials can be corn, wheat, maize meal, sorghum, soybean meal, cassava, oat, etc. The first step of a complete cattle feed processing plant is cleaning. The function of cleaning is to remove the impurities of raw material, such as paper, rope, clods, and iron filings, so as to protect the equipment from damage. The equipment usually used in this process are powder sieve, drum-type pre-cleaner, and permanent magnet.

This process is crushing the raw materials into powder for subsequent processing. Through crushing, the pellets can be more easily absorbed by animals. After removing the impurities, the raw material gets into the feed grinder machine to be crushed. The crushed material is transferred by the bucket elevator to the next section. This section’s main machine is the feed grinder machine.

Material batching is designed according to the nutritional needs of different animals, with the accurate weighing of various ingredients. The mixing system is mixing the raw materials with some nutrients that animal needs. The material of a specific proportion gets into the feed mixer machine. They are fully and evenly mixed. Then the finished pellets contain balanced nutrients.

This is the vital section of the whole animal feed mill equipment for sale. The main equipment used in this process is the animal feed pellet machine. After mixing, the powder is conveyed into the conditioner by the variable frequency feeder. And in the conditioner, the powder is fused with steam. After reaching a certain temperature and moisture content, the powder enters the pelletizing chamber. Then the powder is strongly squeezed by the ring die and the pressure roller to form granules and then the pellets are cut into the desired lengths by the cutter.

After granulation, the feed pellets get through the cooling and screening system. The main equipment of this section is a counterflow pellet cooler and screening system. After pelletizing, the feed pellets get through the counterflow pellet cooler. The equipment can cool pellets from 80℃ to slightly above room temperature for 3-5℃. Then, one part enters the packing machine, and the other too large or too small is repeatedly crushed or pelletized.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

RICHI Machinery, as an animal feed equipment manufacturer, can provide you with various designs according to your different needs. With more than 20 years of experience, RICHI Machinery owns its factory and professional technical team. RICHI pellet machine has been exported to more than 120 countries and regions all over the world. The animal feed mill equipment for sale can produce 2-12mm feed pellets from corn, grass, wheat bran, rice bran, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc.

Besides the 1-2t/h animal feed mill equipment for sale, RICHI Machinery also provides animal feed manufacturing plant of other capacities of 2-100t/h.

When building an animal feed manufacturing plant, the most important is to choose suitable animal feed mill equipment. You can select the equipment according to the following aspects.

Animal feed mill equipment for sale is specializing in the production of feed. It can produce different feed pellets, such as chicken feed pellets, cattle feed pellets, pig feed pellets, rabbit feed pellets, sheep feed pellets, horse feed pellets, fish feed pellets, etc. You can according to your animal kind select the appropriate equipment. For example, if you want to produce shrimp feed pellets, you should build an animal feed manufacturing plant equipped with a three-layer conditioner.

RICHI animal feed mill equipment for sale can produce feed pellets of different sizes, such as 1.5mm baby chicken feed pellets, 3-4mm broiler and laying hens feed pellets, 6-7mm breeding cattle feed pellets, 5-6mm young cows feed pellets, and other sizes you need. It can be customized according to your detailed requirements. The various sizes of feed pellets can be obtained by changing the ring die of the animal feed pellet machine.

What’s more, if you want to produce 1.5mm baby chicken feed pellets, you should build an animal feed manufacturing plant equipped with a pellet crumbler. The pellet crumbler can be used for crushing feed pellets into 0.8-2mm pellets to suit the needs of baby chickens.

The raw materials can be corn, grass, wheat bran, rice bran, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc. You can choose the equipment suitable for your raw material. If the raw material contains grass, the animal feed pellet machine should be equipped with a forced feeder.

If the feed pellets you produce are only for your own farm or animals, you do not need a packing machine. If you produce feed pellets for sale, then there is a need for a packing machine.

The most important thing to choose appropriate animal feed mill equipment for sale is to find a reliable animal feed equipment manufacturer. RICHI Machinery, with CE/ISO/BV certifications, owns its factory and professional technical team. And we have a professional and highly-skilled after-sales service team and a modern and information-based after-sales management system. From the supply of common accessories, and equipment maintenance to repair, we provide customers with a one-stop service to release them out of trouble.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

RICHI Machinery is a pellet equipment manufacturer that mainly focuses on animal feed equipment, biomass pellet machinery, wood pellet machinery, organic fertilizer pellet machinery, parts, etc.

We can provide to build different types of animal feed manufacturing plants to meet different animal feed pellets production needs. We also provide various solutions for customers according to their needs, raw materials, production capacity, etc. Not only can produce a feed grinder machine, feed mixer machine, animal feed pellet machine, pellet crumbler, counterflow pellet cooler, feed batching equipment, puffing equipment, and automatic electric control equipment, but also can provide you with complete sets of animal feed equipment.

RICHI Machinery can provide you with customized design, from design to production, from testing to delivery, from delivery to installation, from installation to training, and after-sales service of the full master turnkey engineering services. We have a lot of successful project cases and field works available to visit. If you want to learn more about the animal feed mill equipment for sale, just contact us directly and we are always here for you.

With the development of the breeding industry, more and more people want to build animal feed factories. So what should you pay attention to when you start the animal feed factory?

The first thing is to determine the raw material. After determining the raw materials, you can choose the factory site that is convenient to acquire these raw materials. Then selecting the animal feed equipment is a top priority for you. When selecting high-quality animal feed equipment, you should pay attention to the following factors.

Firstly, you should pay attention to the raw materials. The equipment should be suitable for the raw materials. Taking an example, if the raw materials are powder, there is no need for a feed grinder machine. Also, if the raw materials contain grass, the animal feed pellet machine should be equipped with a forced feeder.

Secondly, the kind of animals should be considered. Different animals need different animal feed mill equipment of various designs. RICHI animal feed equipment can produce 1.5mm baby chicken feed pellets, 6-8mm milking cattle feed pellets, 5-6mm young cows feed pellets, and shrimp feed pellets. If you want to produce 1.5mm baby chicken feed pellets, the animal feed pellet production line should be equipped with a pellet crumbler. The pellet crumbler is to crush feed pellets into 0.8-2mm pellets to suit the needs of the baby chicken. In addition, if you want to produce shrimp feed pellets, the animal feed manufacturing plant should contain an animal feed pellet machine equipped with a three-layer conditioner.

Thirdly, the design of the equipment also depends on the finished pellets. For instance, by adjusting the distance between the ring die and the cutter, feed pellets of different lengths can be acquired.

RICHI Machinery specializing in the production of animal feed equipment for more than 20 years. We can provide you with different animal feed mill equipment of various designs. If you want to learn more about this, just send an inquiry to us!

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Small animal feed manufacturing plant generally refers to those similar to family workshops, which require low site requirements. You only need to buy a feed grinder machine, a feed mixer machine, and a sealing machine and then purchase some raw materials, such as fish meal, corn, soybean, and rapeseed meal. Basically, you have the ability to produce and process feed.

Generally, establishing a small animal feed manufacturing plant requires an independent plant area, and the production workshop needs to meet the production process requirements. At the same time, the traffic shall be convenient, in order to prevent the products from being polluted, reduce the noise and reduce the pollution to the living area. What’s more, the site also needs to have good lighting, dust removal, ventilation, and fire-fighting measures.

In addition, the production and processing equipment should be carefully selected. The equipment shall be simple and efficient, and pay attention to production performance. You can choose equipment manufacturers that are easy to purchase parts and have convenient maintenance services. Relatively speaking, the return on investment of feed plants is relatively high. Despite the fierce market competition, if small feed factories can continuously improve the product quality, make great efforts in team building and carry out intensive work in local regional markets, the prospect is still considerable.

RICHI Machinery, as an animal feed equipment manufacturer, regards product quality as the life of the enterprise. We provide different types of animal feed mill equipment for sale to meet different animal feed production needs. We provide various solutions for customers according to their needs, raw materials, production capacity, etc. If you are interested in the equipment or have any questions, you can send an inquiry to us at any time.

At present, with the continuous development of aquaculture, more and more aquatic extruders are used in many areas, and there are more projects to install and use aquatic extruders. Among these many animal feed equipment manufacturers, because the production management personnel or engineering installation designers of the manufacturers have various understanding of the production characteristics of the aquatic extruder, the installation methods and supporting facilities of the extruder are also different. However, the selection of the installation mode of each part of the whole aquatic extruder and the completeness of its supporting facilities will directly affect the stability of the working performance of the extruder.

The production of high-quality fish feed must rely on scientific and reasonable processing technology, and make it combined with advanced, reliable, and stable processing machinery. In this respect, the choice of processing equipment is particularly critical. So how can you get high-quality feed? This is where the fish feed production line comes in handy.

When producing ordinary fish feed, the size of its raw materials is required to be 40-60 mesh. But when producing the special aquatic pellet feed (shrimp feed, eel feed, turtle feed, etc), the size of raw materials must reach more than 80 mesh. To achieve the ideal size of the crushed, the previously used hammer mill is not adapted to the production of fish feed. A complete fish feed production line is equipped with a feed grinder machine and micro crumbler. Micro-crushing of fish feed is often used in the second crushing process, that is, first coarse crushing and then micro-crushing.

RICHI Machinery owns this micro crumbler. The micro crumbler is widely used in the crushing of raw materials of fish feed. The key parts are all imported, and it is easy to operate and maintain.

What’s more, the production of fish feeds requires a high degree of paste and stability in water, which at this time must strengthen the conditioning conditions. Due to the extension of the material conditioning time, the material and steam can be fully mixed evenly. And in the high-temperature starch paste and protein denaturation, paste degree increased to enhance the bonding force of the internal part of the particles, killing a variety of harmful bacteria such as Salmonella. And the appearance of the granule is bright and clean, not easy to be eroded by water. This not only improves the stability of the particles in the water but also improves the palatability and digestibility of the feed pellet. Ensuring that the fish have a long feeding time. Also, this prevents water pollution.

The most common equipment is the multi-layer conditioner before pelleting. RICHI Machinery can provide you with a fish feed production line with a three-layer conditioner. Inside the conditioner, the raw material is fully contacted with the saturated dry steam.

Feed puffing technology is mainly used in the production of special aquatic feed, pet feed, and other animal feed. In addition to the advantages of the general full-price pellet feed, the puffed feed also has the ability to improve the digestive absorption rate of fed animals and can effectively prevent animal digestive tract diseases.

RICHI Machinery can provide you with the equipment with such technology. The fish feed extruder of a complete fish feed production line is suitable for the processing of various floating and sinking aquatic feed, suckling pig feed, pet feed, etc.

Quality is the life of an enterprise. To produce fish feeds and obtain high-quality feeds of different species that meet the requirements, one should choose the applicable equipment according to the species they produce. RICHI Machinery has its own factory and professional production equipment. With more than 20 years of experience in the industry, RICHI Machinery can provide customers with different recommendations.

If you are interested in this industry, you can just send an inquiry to RICHI Machinery and we will provide you with professional advice.

With the development of the breeding industry, the need for feed is increasing. So what equipment should be needed? Many customers who want to get involved in the feed processing industry will ask this question at the beginning. Today, RICHI Machinery will give you a brief introduction to let you know about animal feed equipment. As the actual needs of each customer are different, each animal feed pellet production line provided by RICHI is customized.

Animal feed equipment is usually selected according to the production scale, production varieties, and production technology. Therefore, different animal feed manufacturing plants often use different equipment. However, some basic equipment for feed processing is consistent. The process flow generally includes raw material receiving and cleaning equipment, conveying equipment, crushing equipment, batching equipment, mixing equipment, granulating equipment, dust removal equipment, packaging equipment, and central control system.

In this process, the impurities in the raw materials are first removed by the impurity removal equipment and then transported to the silo through the receiving equipment and demagnetizing equipment as planned. The production line equipment includes receiving devices, conveying equipment, powder sieve, drum type precleaner, and permanent magnet.

The batching process is to weigh the raw materials in the batching bin from the feeder under each batching bin to batching according to the formula requirements. After each raw material is weighed by the batching scale, it is transported to the powder storage bin. The ingredients are weighed out from the silo. These weighed raw materials enter the powder silo, add a small number of materials and premixes, and then weigh them manually and put them into the silo for mixing. The quality of batching process directly affects the accuracy of product batching.

The crushing process refers to that the raw materials to be crushed in the silo are sent to the crusher for crushing into powder, and then sent to the silo for mixing by the conveyor before use. The purpose of this process is to control the particle size of the material. The design efficiency of the feed grinder machine in this process determines the capacity of the process equipment, and it is also the process with the largest energy consumption in the production of powdery materials.

In the mixing process, various crushed raw materials are discharged into the mixer from the mixing bin. According to the needs, grease is added to the feed in the mixer through the liquid adding system, so that each component is mixed evenly to achieve the desired mixing effect. In order to ensure the efficiency of the feed mixer machine, the maintenance personnel must regularly check and repair the equipment and regularly test the efficiency of the feed mixer machine.

After magnetic separation and conditioning from the granulating bin, the mixed materials are sent to the pelletizing chamber of the animal feed pellet machine and compressed into pellet feed. It is cooled by the counterflow pellet cooler and screened by the screening equipment to obtain standard particles. During quenching and tempering, the steam volume shall be adjusted according to the requirements of particle type, and the ring die shall be selected according to the requirements of particle process quality. During cooling, the counterflow pellet cooler shall be adjusted according to the type of pellets, indoor temperature and humidity, season, and other factors to achieve qualified particle temperature and humidity.

The feed is weighed by the packaging scale from the finished product warehouse, loaded into the packaging bag, and then transported to the warehouse by the transport vehicle for stacking.

This is a complete production process of the RICHI animal feed pellet production line. RICHI Machinery can provide you with customized designs. Therefore, if you want to start a suitable and easy-to-use animal feed factory project to meet your needs, you can consult us directly online for more detailed technical support.

For those who have been engaged in or come into contact with poultry or aquaculture, pellet feed is a common feeding feed. Pellet feed is only an external morphological difference of feed. It just gathers several feeds with appropriate nutritional ratios and components of raw materials together, compresses them into a fixed form through feed, and then facilitates feeding and preservation.

Many people don’t necessarily know how to make pellet feed. Let’s learn about this machine. This machine for producing pellet feed for animals is called the animal feed pellet machine. In fact, there are many other names, such as pellet feed mill, feed granulator, and pellet feed pelletizer. This machine belongs to feed granulation equipment.

Generally, it is a processing machine that takes various crops or straws, such as corn, rice husk, straw, or various kinds of grass as raw materials, smashing the raw materials through the machine. Then other nutrients required by animals are added. After that, raw materials are pressed into granular feed.

At present, a lot of machinery and equipment is used in many breeding industries, which can not only reduce labor intensity but also improve the level of feed.

The structure of the animal feed machine is relatively simple, easy to learn, and relatively simple to operate. After the raw materials are made into feed granules, they can also preserve the same water content, and after they are made into granules, they are also more conducive to storage and preservation. Therefore, for those feedlots, the animal feed pellet machine is one of the necessary equipment and has gradually become a good helper for many farmers to get rich. When raw materials particles or powders are put into the animal feed pellet machine, if the moisture content is too low, the pellets will be soft and have poor formability. If the moisture content is too high, the surface will be rough and affect the appearance of the pellets. Therefore, the moisture content of raw materials is generally controlled at 13-15%.

When the animal feed pellet machine is powered on, the motor transmits the power to the grinding plate in the pelletizing chamber to drive the two pressing rollers to rotate. After the raw materials are put into the feed hopper, the raw materials will turn into paste under the rolling of the two pressing rollers, and finally, be extruded from the template under the extrusion of the pressing rollers. After sending out of the pelletizing chamber, the feed is cut into a certain length through the cutter. After the pellets are cooled, they can be packaged and stored.

The rapid development of the breeding and feed industry had greatly promoted the development and progress of animal feed equipment. Equipment such as animal feed pellet machine has been more widely used, and breakthroughs have been made in technology. The current animal feed mill equipment for sale ensures that the nutrition will not be lost after the raw materials are made into feed pellets. The particle surface is smoother, and the hardness is more suitable for animal digestion, and it can kill harmful microorganisms in the feed. So it has become ideal equipment for reducing the breeding cost and improving economic benefits.

RICHI Machinery pursues the purpose of product quality first. The main parts and wearing parts are made of high-quality wear-resistant materials, coupled with advanced processing technology. If you want to learn more about the equipment, just contact us.

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@pelletizermachines.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production